Process

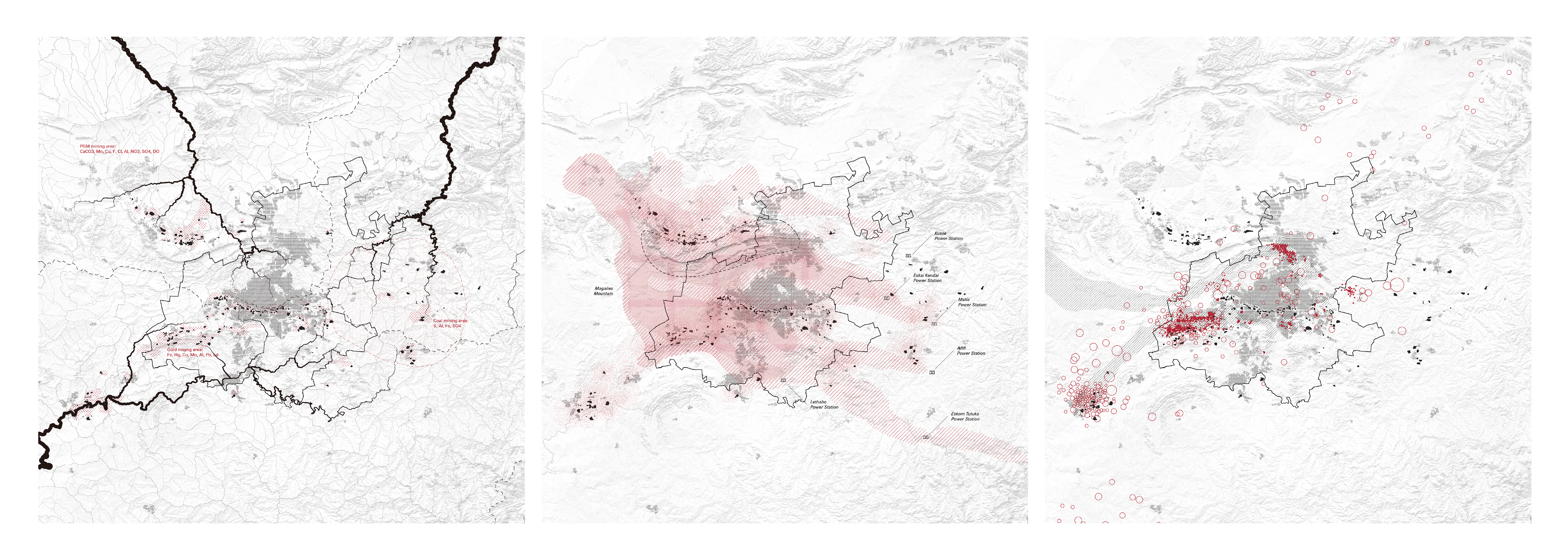

Witwatersrand Basin

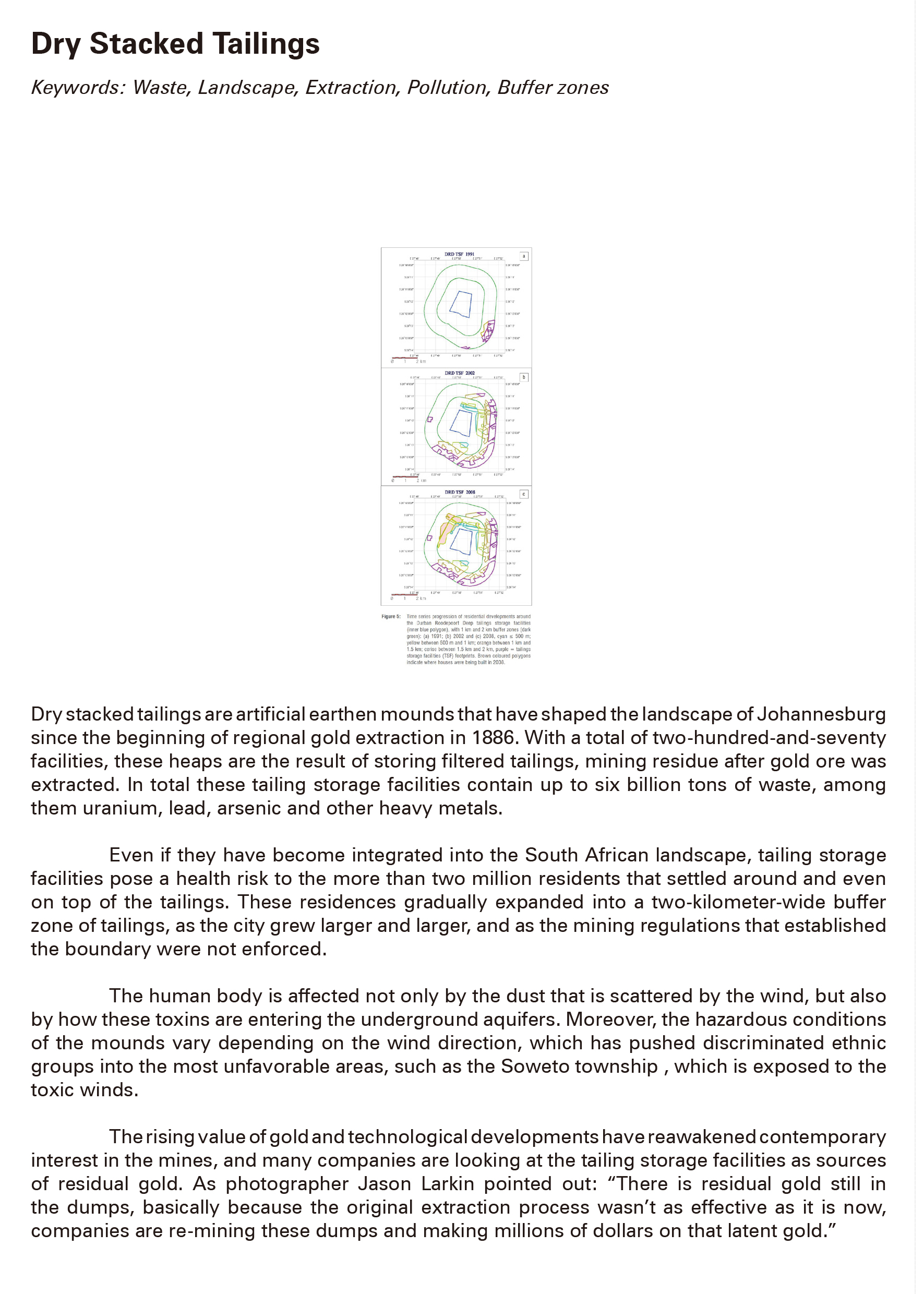

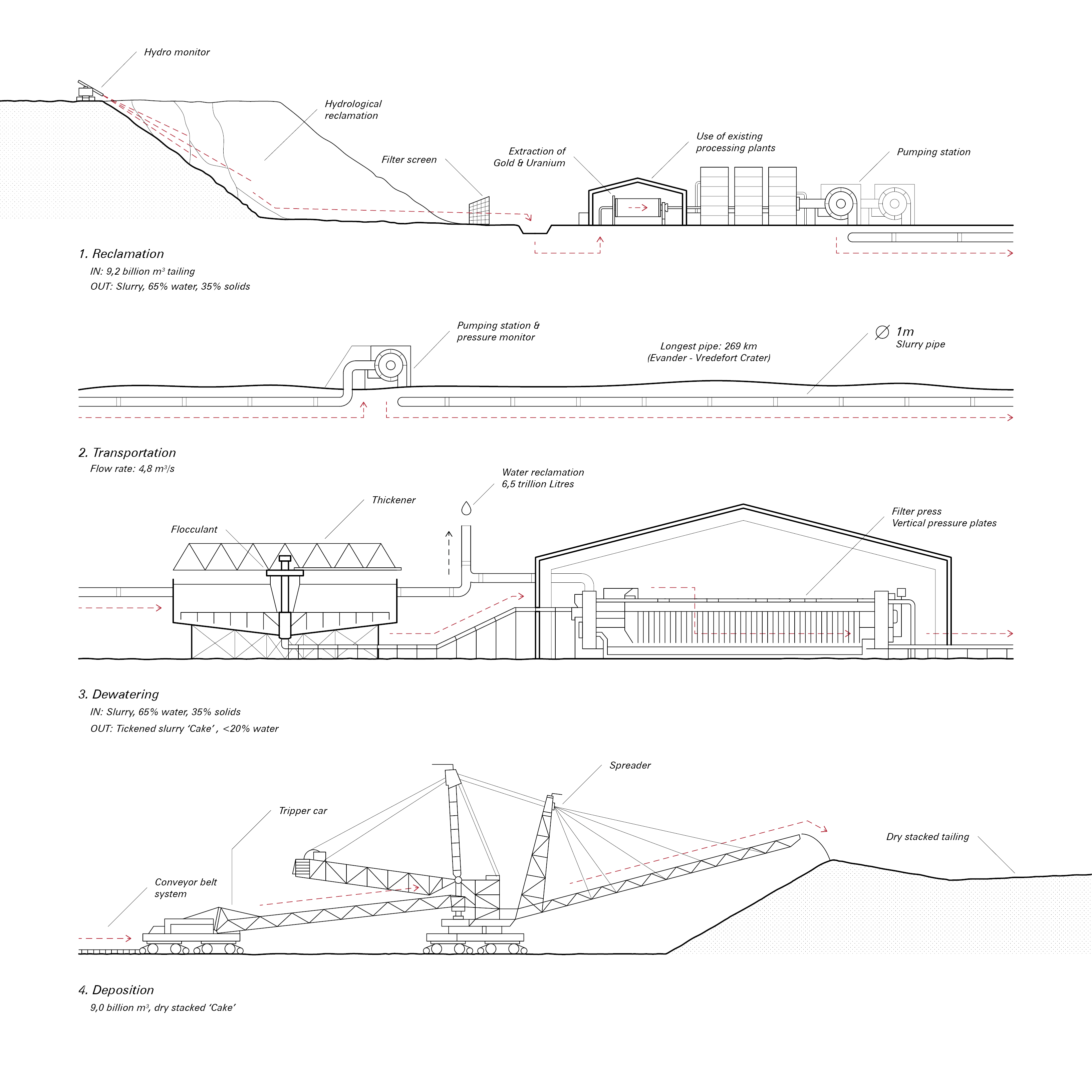

The solid tailing material is hydrologically reclaimed using water jets. The liquid substance called ‘slurry’ is filtered, collected and transported to local processing plants to take out the remaining gold and uranium. The left-over slurry is transported to the central tailing facility through underground pipes with a diameter of 1m, allowing for a flow rate of 4,8 m3 /s. In the central facility, a dewatering process that uses a Thickener and subsequently a Verticle Press transforms the ‘slurry’ into ‘cake’, a material that consists for less than 20% out of water. The cake is transported by conveyor belts to site of deposition, where it is stacked by a system of a tripper car and spreaders.